We offer comprehensive options for conventional and cnc materials processing

CNC

milling

CNC milling opens up endless possibilities as we can process a wide range of materials including metals, plastics and composites. With our technology, we are able to create even the most complex shapes and geometries, be it impressive 3D surfaces or precise cavities.

Your satisfaction is our main goal, which is why we always adhere to the highest quality standards so that every part you get from us is flawless and exactly as you expect.

GALLERYCNC

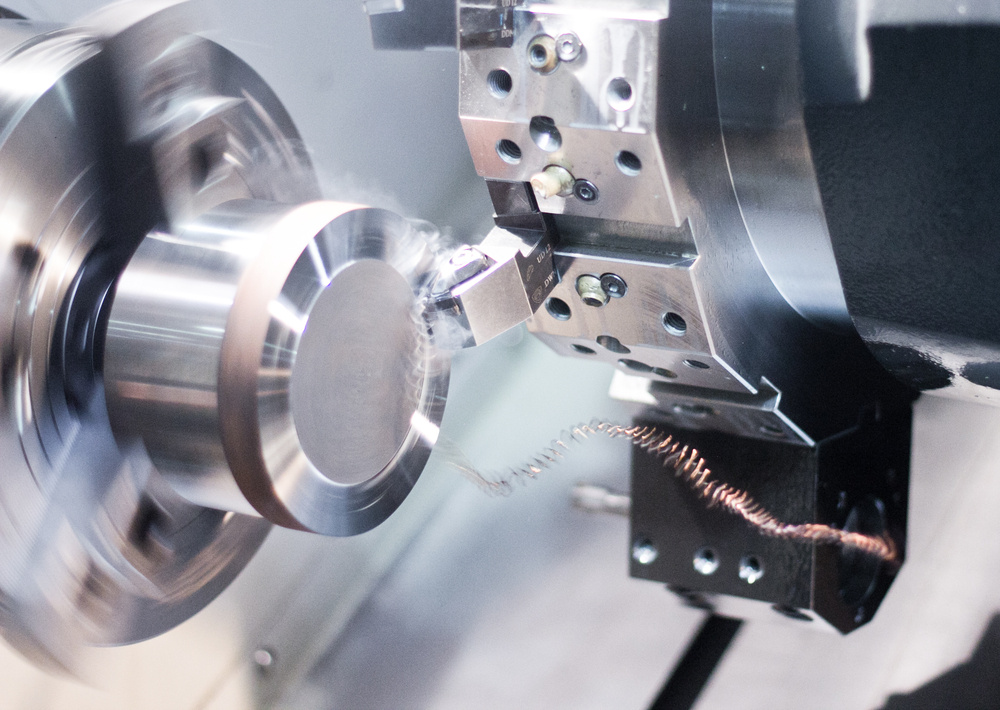

turning

With the CNC lathes we have, we can ensure the production of parts with high demands on precision and quality.

An automated process minimizes the risk of errors and increases production efficiency. CNC turning also makes it possible to produce complex shapes and geometries that would be difficult or impossible to produce manually.

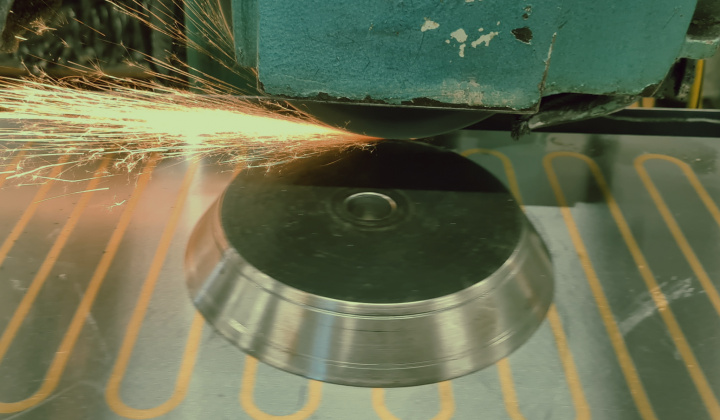

Grinding

Point grinders and flat grinders enable us to efficiently and accurately machine grind metal parts with maximum precision.

It is a reliable and fast way to produce precise metal parts such as gears, shafts or bushings.

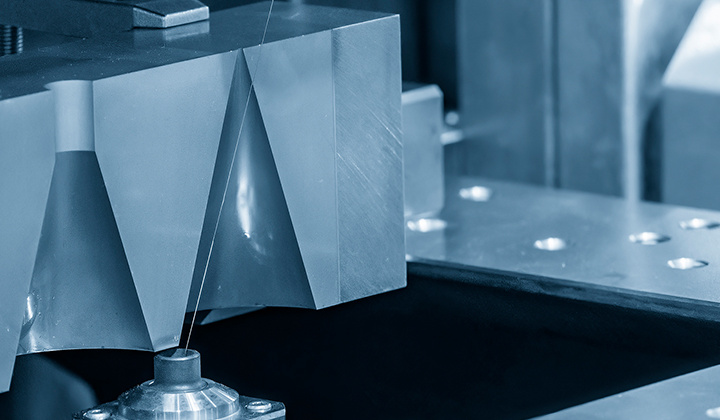

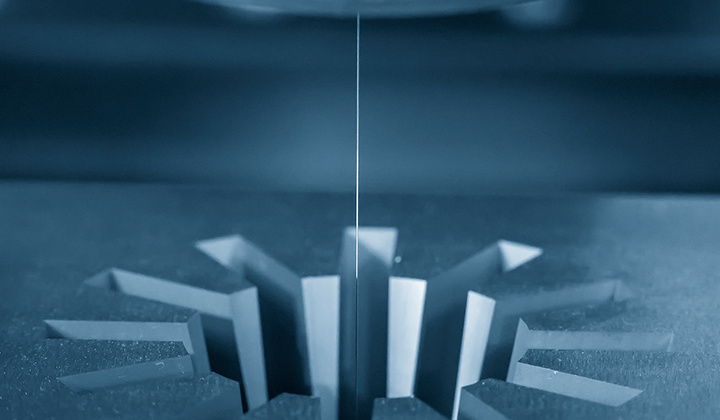

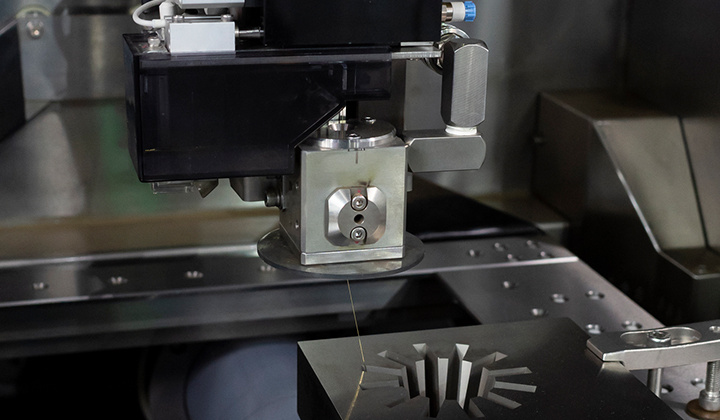

EDM

This method uses an electrical discharge that creates a gentle arc between the electrode and the work metal. This arc gradually removes material from the metal.

The main advantage of this technology is the machining of problematic shapes and materials, but also of very precise and very small dimensions. In this way, it is possible to achieve machining accuracy of thousandths of a millimeter and a surface roughness of Ra 0.2, which means that grinding can also be replaced with this technology.

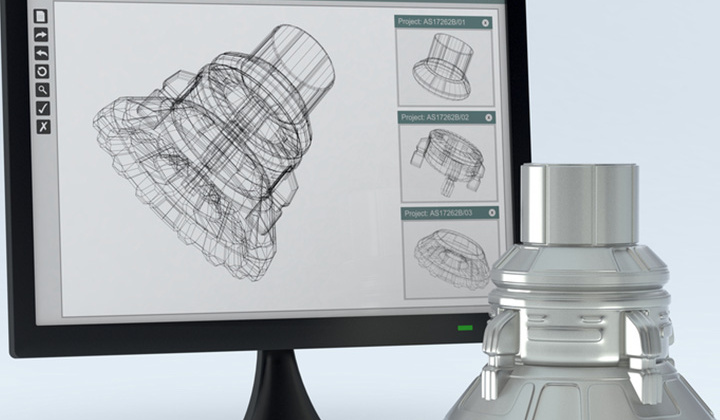

3D

measurement

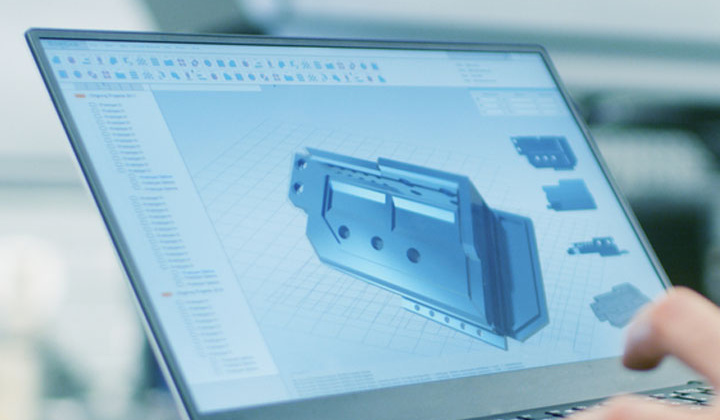

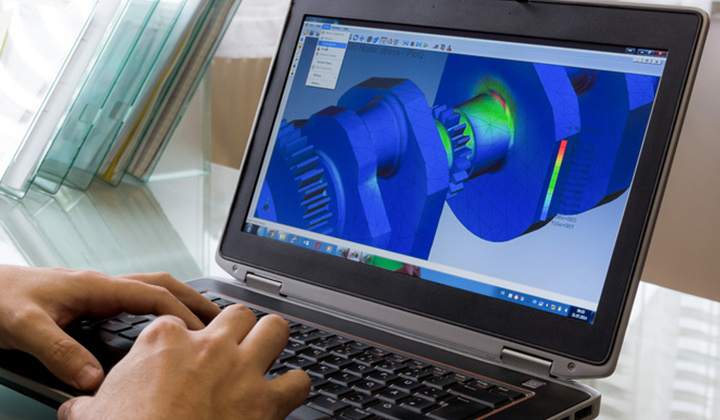

CAD CAM

We use CAD/CAM systems for the innovation and effectiveness of your designs in our company. With our experienced team, we create exceptional designs that will meet your requirements.

The software enables fast and accurate applications and improved collaboration, saving time and ensuring accuracy. Parametric modeling and automated processes increase productivity and allow easy design adjustments.